WOOL 50 LF

Bonded 50% chrome-alumina

High corrosion resistance combined with a high thermal shock resistance. Good homogeneity with reduced chrome sublimation and linear thermal expansion.

Typical application

Mainly used for glass contact and superstructure application for insulation glass furnaces.

WOOL 50 LF is made of grains from a unique manufacturing process, the very specific chemical and crystallographic structure provides high corrosion resistance with several others benefits such as :

- smooth corrosion profile,

- lower joint corrosion thru better joint closure after heat-up,

- good electrical resistivity,

- lower chrome sublimation.

For crown application, refer to ZIRCHROM HC.

WOOL 50 LF is also a potential material for overcoating applications.

Chemical and physical properties

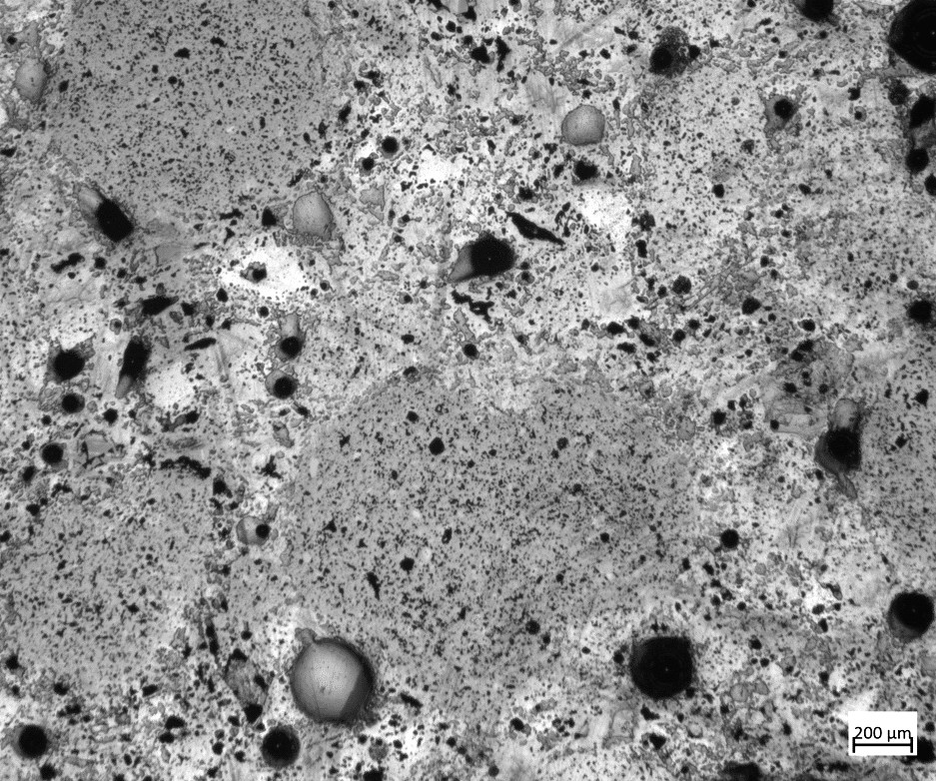

Microstructure

Typical chemical properties

Typical crystallographic analysis

Main phase:

- Cr2O3-Al2O3 solid solution

- monoclinic zirconia

Physical characteristics

| Description | International standards | British standards |

|---|---|---|

| Cold crushing strength | 75Mpa | 10,878psi |

| Refractoriness under load 2 105Pa, 0.5% at | 1,477°C | 2,691°F |

| Coefficient of thermal expansion | 8.2 10-6K-1 | 4.5 10-6°F-1 |

| Thermal conductivity at 1,000°C | 2.6W.m-1.K-1 | 18BTU in hr-1ft-2°F-1 |

| Porosity | 13.7% | 13.7% |

| Typical bulk density | 3.5g/cm3 | 218pcf |

Storage

The bonded 50% chrome-alumina, WOOL 50 LF solution must be stored in a dry environment protected from weather conditions.

Related products

Sintered 50% chrome-alumina

High corrosion resistance. Good homogeneity with reduced chrome sublimation and linear thermal expansion.