A1148

Sintered dense high alumina 93%

High corrosion resistance. Homogenous structure with excellent glass contact properties.

Typical application

A1148 is available in large blocks for glass melting of high quality ophthalmic, optical and other specialty glassese.

With almost no porosity, it provides good corrosion resistance with very minimal stone, seed and cord defects.

Chemical and physical properties

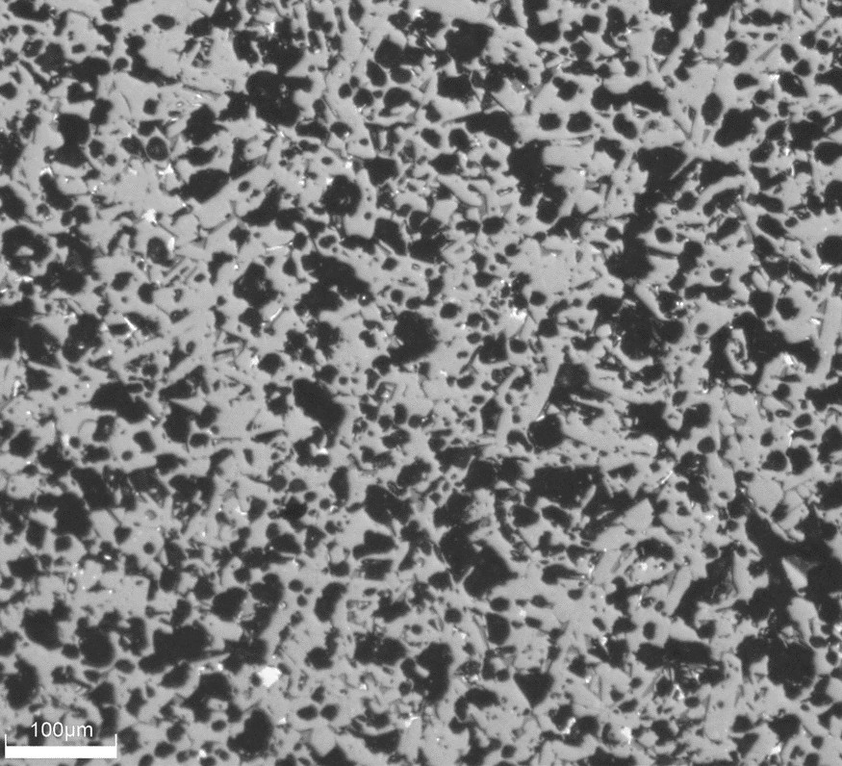

Microstructure

Typical chemical composition

Typical crystallographic analysis

Main phase:

- corundum

- mullite

Physical characteristics

| Description | International standards | British standards |

|---|---|---|

| Refractoriness under load of 2 105 Pa, at 0.5% | >1,675°C | 3,047°F |

| Cold crushing strength | 448Mpa | 64,977psi |

| Linear thermal expansion | 8 10-6K-1 | 4.4 10-6°F-1 |

| Thermal conductivity at 1,000°C | 4.1 W.m-1.K-1 |

28.4 BTU |

| Apparent porosity | 1% | 1% |

| Typical bulk density | 3.4g/cm3 | 212pcf |

Storage

The sintered dense high alumina 93%, A1148 solution must be stored in a dry environment protected from weather conditions.

Related products

Sintered high-alumina 93%

High alumina content sintered material. Very good glass contact properties with the low glass defect potential.

Available in complex and large shapes.

Sintered high-alumina 99%

Highest alumina content sintered material. Remarkable resistance to vapours corrosion. Available in standard brick format.

Void-free, electrofused 95% alumina (alpha-beta alumina)

Excellent glass contact properties with extremely low defect potential.

High resistant to alkali vapor and creep for superstructure application.

Void-free structure enabling longer lifetime.

Alumina mortar for sealing and jointing

High alumina heat-setting cement to joint and seal Alumina and alumina-zirconia-silica (AZS) refractories.