T1186 ZR

Sintered dense tin oxide

High electrical conductivity. Very high corrosion resistance with excellent glass contact properties.

Typical application

T1186 ZR electrodes are used for electrical boosting or direct melting. Available in large size with rectangular or cylindrical cross section.

Homogenous structure enabling a uniform electrical resistivity.

T1186 ZR has an improved thermal stability leading to higher corrosion resistance at high temperatures while maintaining low electrical resistivity.

Chemical and physical properties

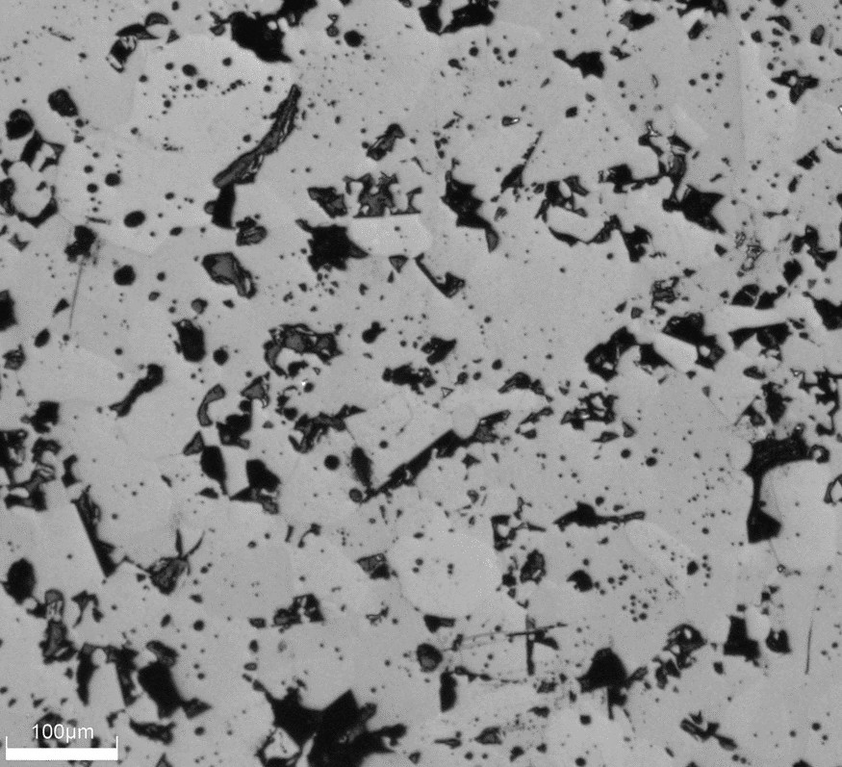

Microstructure

Typical chemical composition

Typical crystallographic analysis

Main phase:

- stannic oxide

Physical characteristics

| Description | International standards | British standards |

|---|---|---|

| Apparent porosity | 2.5% | 2.5% |

| Typical bulk density | 6.6g/cm3 | 412pcf |

Storage

The sintered dense tin oxide, T1186 ZR solution must be stored in a dry environment protected from weather conditions.

Related products

Sintered dense tin oxide

High electrical conductivity. High corrosion resistance with excellent glass contact properties.

Sintered dense tin oxide

High electrical conductivity. High corrosion resistance with excellent glass contact properties.

Void-free electrofused zirconia with improved high electrical resistivity

Excellent corrosion resistance and glass contact properties combined with a very high and stable electrical resistivity while providing the lowest potential for seed and blister formation.

Void-free electrofused 94% zirconia

Excellent corrosion resistance and glass contact properties with the lowest potential for seed and blister formation.