PROMOLD E

Sintered alumina-zirconia-silica (AZS) with 30% zirconia

Made of alumina-zirconia-silica (AZS) grains. Good resistance to vapours corrosion. Available in standard brick format.

Typical application

PROMOLD E is dedicated to superstructure application of enamel glass furnaces.

Very resistant to vapours corrosion of a broad spectrum of enamel chemistries and adapted to discontinuous operating conditions of enamel glass production.

If mortar is required, use PROMOLD MORTAR.

Chemical and physical properties

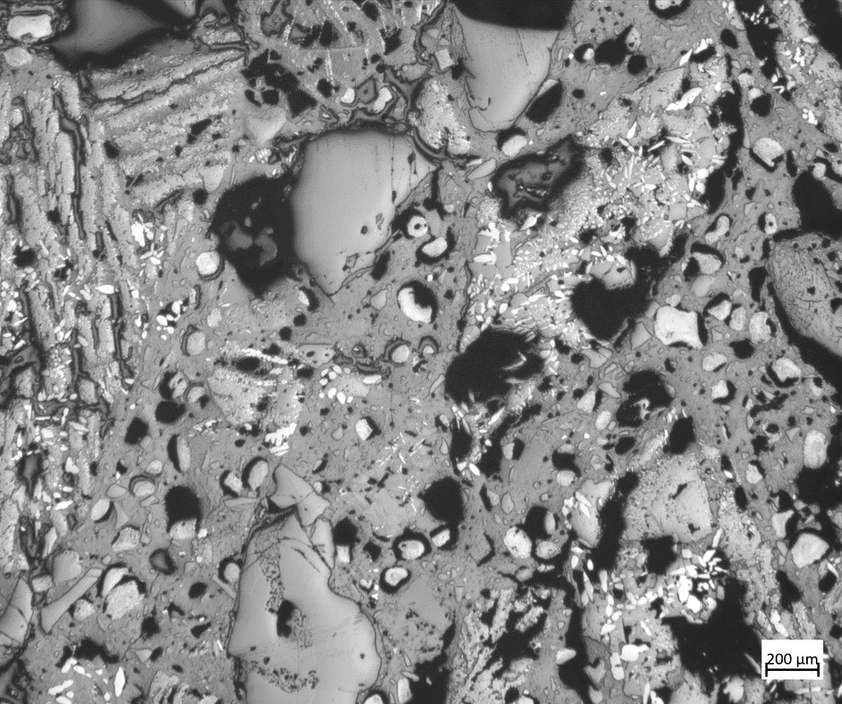

Microstructure

Typical chemical composition

Typical crystallographic analysis

Main phase:

- corundum

- monoclinic zirconia

Physical characteristics

| Description | International standards | British standards |

|---|---|---|

| Refractoriness under load of 2 105 Pa, at 0.5% | 1,650°C | 3,002°F |

| Cold crushing strength | >1000Mpa | >14,504psi |

| Linear thermal expansion | 6 10-6K-1 | 3.3 10-6°F-1 |

| Thermal conductivity at 1,000°C | 2.7 W.m-1.K-1 | 18.7 BTU in hr-1ft-2°F-1 |

| Apparent porosity | 14.5% | 14.5% |

| Typical bulk density | 3.1g/cm3 | 194pcf |

Storage

The sintered alumina-zirconia-silica (AZS) with 30% zirconia, PROMOLD E solution must be stored in a dry environment protected from weather conditions.

Related products

Bonded alumina-zirconia-silica (AZS) with 30% zirconia

Made of alumina-zirconia-silica (AZS) grains. High corrosion resistance to alkali or boron vapours. Available in complex and large shapes.

Bonded alumina-zirconia-silica (AZS) with 30% zirconia

Made of alumina-zirconia-silica (AZS) grains. High resistance to glass corrosion. Available in large format with large range of thickness.

Bonded alumina-zirconia-silica (AZS) with 30% zirconia

Made of alumina-zirconia-silica (AZS) grains. Excellent thermal shock resistance combined with high resistance to vapours corrosion

Sintered zircon-mullite with 20% zirconia

Made of fused zircon-mullite grains. High resistance to vapours corrosion. Available in complex and large shapes.

Sintered zircon-mullite with 20% zirconia

Made of fused zircon-mullite grains. High resistance to vapours corrosion. Available in standard brick format.